What Is Industrial Safety and why it is important?

The main goal of industrial safety is to prevent fatalities, serious injuries, and occupational diseases. Before we can grasp industrial safety, let’s define safety.

Safety is the condition of being free from risks, dangers, and accidents that could cause physical hurt, financial loss, property damage, or even death. Safety is the absence of risk, according to the most fundamental definition. (The attribute of safety, freedom from risk, freedom from harm, injury, or loss.)

What is Industrial Safety?

Reduce, control, and eliminate dangers from the industries or industrial units are the main management activities that are concerned with industrial safety. (Policies and safeguards put in place to guarantee plant and factory workers are protected from risks that could result in injury are referred to as “industrial safety”).

Every sector has a basic need for safety. The workplace safety programme fosters a favourable environment and could raise employee morale.

Industrial facilities must always put safety first, from safeguarding workers from mishaps to guarding against catastrophic equipment damage that could need expensive downtime and repairs.

What is Industrial safety management?

A division of management is industrial safety management. In order to lessen or completely avoid industrial accidents, it encompasses the administrative tasks of setting objectives and planning, organising, managing, and directing. It also includes encouraging employees to work safely.

Industry needs safety because it protects workers and assets by reducing risks, hazards, accidents, and near-misses.

Why industrial safety is important?

- The primary goal of safety in the workplace or in any other setting is to avoid accidents and other dangers that can result in significant damage to people’s lives, their property, and the environment.

- It is the moral duty of the industry to consider employee protection because every single person in the sector wants to work in a secure and protected environment.

- Because there are millions of industrial accidents per year, which cause millions of lost man and machine hours in production time.

- Families, friends, and coworkers’ lives are forever altered by a major workplace accident or death. Because human suffering and loss are unfathomable and unbearable, maintaining industrial safety is essential.

- Safety is crucial for preventing environmental harm from industrial mishaps as well as for reducing monetary losses, property damage, accident risk, injury risk, and even fatalities.

Industrial safety topics:

- General Safety

- Occupational Health and Safety

- Process Safety

- Material Safety Datasheet

- Workplace Safety

- Fire Safety

- Electrical Safety

- construction safety

- Ergonomics safety

- Working at height safety

- Chemical safety

- Radiation Safety

- Environmental Safety

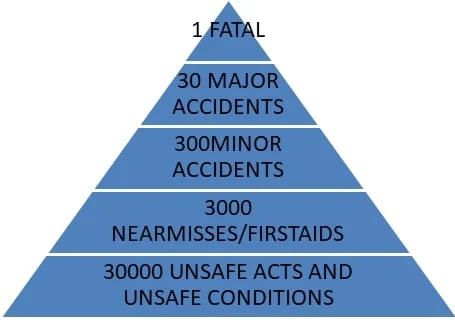

Hazard Pyramid:

Due to the 30,000 risky behaviours and the 3000 near misses or first aid that the unsafe condition creates. 300 minor accidents result from 3000 near misses, 30 major accidents from 300 minor accidents, and 1 fatality from 30 major accidents. Therefore, it is crucial to stop the development of harmful behaviours and environments.

12 steps of full safety in the industry:

- Hazard analysis

- Use of PPE(Personal protective equipment)

- Use of sop (Standard operating procedure)

- Positive isolation

- Work permit system

- Gas safety

- Right tools and tackles

- Confined space permit

- Working at height

- Traffic rules

- Safety in multi activities

- Change management.

Some life-saving rules in the industry:

- Working under the influence of alcohol or illegal drugs

- Non-compliance to the rule of confined space

- Starting the job without a work permit /clearance

- Non-fulfillment of conditions essential to ensure safe welding and gas cutting.

- Tempering of locks in positive isolation.

Accident prevention methods:

- 5 e’s for accident prevention

- Preventing unsafe acts

- Preventing unsafe conditions

- Safety tag system

- Safety in hose keeping

- Employees’ training in safety

- Hazard checklist

- Colour coding

- Motivating employees for safety

- Safety auditing

5 e’s for accident prevention:

- Engineering

- Education

- Enforcement

- Enthusiasm

- Evaluation

How to develop a safety culture:

- Management safety policy

- Total loss control management.

- Accident investigation.

- Plant and facility inspection.

- Statutory laws and standards.

- Safety committee meeting.

- Group meeting management.

- General safety promotion (posters, banners, signs, etc.)

- Personal protection.

- Supervisory training.

- Employee training.

- Selection and employment procedures.

- Reference library.

- Occupational health and hygiene.

- Fire prevention and loss control.

- Accident analysis.

- Personal safety communications.

- Job safety analysis (JSA)

- job safety Observations (JSO).

- Records and statistics.

- Emergency care.

- Product liability.

- Off-the-job safety.

- Incident recall and analysis.

- Traffic safety/transport.

- Security facility.

- Ergonomic application.

- Pollution and disaster control.

Safety Terminologies:

What is Nearmiss?

A near miss is an unexpected event that may have harmed, sickened, or damaged something but didn’t.

What is Firstaid?

First aid is the fast, skilled care given to the sufferer in the event of an accident, injury, or illness by a qualified first responder before medical assistance is available.

What is Risk?

Risk (R=L*C) is the likelihood and impact of a certain hazard event materializing.

What is an injury?

A bodily hurt or damage is described as physical harm or damage brought on by the exchange of energy (typically acute, mechanical, chemical, thermal, or other environmental) exceeding the body’s threshold.

What is Disabling injury?

Any injury that results in death, permanent disability, or any level of temporary total incapacity that persists beyond the day of the injury is considered to be debilitating.

What is an accident?

It is an unanticipated or unplanned event that might or might not cause harm, damage, lost property, or even death.

What is personal protective equipment?

It is the gear used to shield a person from dangers like sparks, gases, dust, and more. It serves as a separation between people and hazards.

Faq’s for industrial safety?

What is an incident?

Any occurrence that could lead to:

- Illness and injury.

- Material loss.

- Release into the environment

- Interruptions to business, etc.

What is the hazard?

Any real or potential condition that can cause injury, illness, or death to personnel, damage to or loss of a system, equipment, or property, or damage to the environment.

For example, workers could be electrocuted by touching exposed contacts in electrical pannel containing high voltage.

What is a mishap?

An unplanned event or series of events resulting in death, injury, occupational illness, damage to or loss of equipment or property, or damage to the environment.

For example, workers were electrocuted by touching exposed contacts in electrical pannel containing high voltage.

Other QHI Free Courses

Certified Six Sigma White Belt (CSSWB) (English)

Mini Course – Six Sigma Awareness (English)

1 Comment

ISHWARGOUDA PATIL

May 28, 2024Industrial safety course free certicficate thanks