How should the automotive industry handle 4M change?

In this article we come to know how 4M change management is useful in Automotive Industry

Why 4M Change Management?

To track 4M Change (Operator Change, Machine Change, Tool Change, Material Change, and Method Change) management for anticipated change (new operator, operator on leave, machine/tool PM, New Machine, New Gauge, and New Instrument), as well as unforeseen change (Tool breakage, power failure, machine breakdown etc.)

Scope Of 4M Change Management?

Applicable for all internal changes in process & brought out parts (BOP)

Responsibility Of 4M Changement?

| S.No | Activity | Responsibility | Frequency |

| 1 | Change Point Control Board | Supervisor | Daily |

| 2 | Change Approval | Plant Head / Quality Head | Daily |

Definition Of Change Management

Changes to products or processes are characterized as deviations from control plans, work instructions, skill matrices, and customer approval for “man, material, machine, and the method employed for.”

Plan Amendment (Expected Amendment):

Changes that take place with advance notice to the affected party and specific steps taken to control the incidence of product non-conformity at the change point.

A plan change example would be:

Device undergoing planned maintenance

An instrument for Plan Maintenance

A new operator is hired for the machine an experienced operator returns to work

A new tool or equipment was utilized

Un- Plan Change (Unexpected Change):

To prevent the incidence of product non-conformity at the change point, change that takes place without prior notification to the relevant party and sudden, defined action is required.

Example of Un-plan Change :

Under Breakdown Machine

Die / Tool under Failure

Tool failure

Power Outage

various grades of material

used an unapproved source of material

Any modifications made to a process involving a man, a machine, a material, or a method must be instantly updated on the 4’M change monitoring board and documented in the 4’M Change Tracking Sheet.

The appropriate team notifies the 4’M change accountable individual of any changes in people, things, methods, and machines that take place in his region.

On the 4’M change control board, the change details for Man, Material, Method, and Machine should be emphasized.

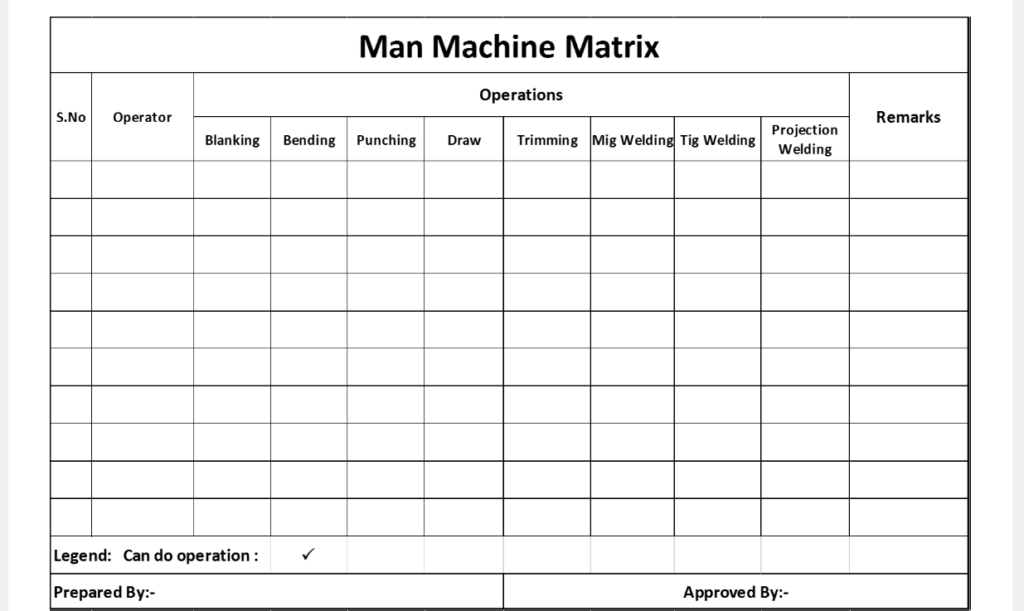

As per the man-machine matrix, identify the change in man.

The 4’M shift Within 30 minutes, the accountable party must update the 4’M change tracking sheet and take the necessary action in accordance with 4’M WI.

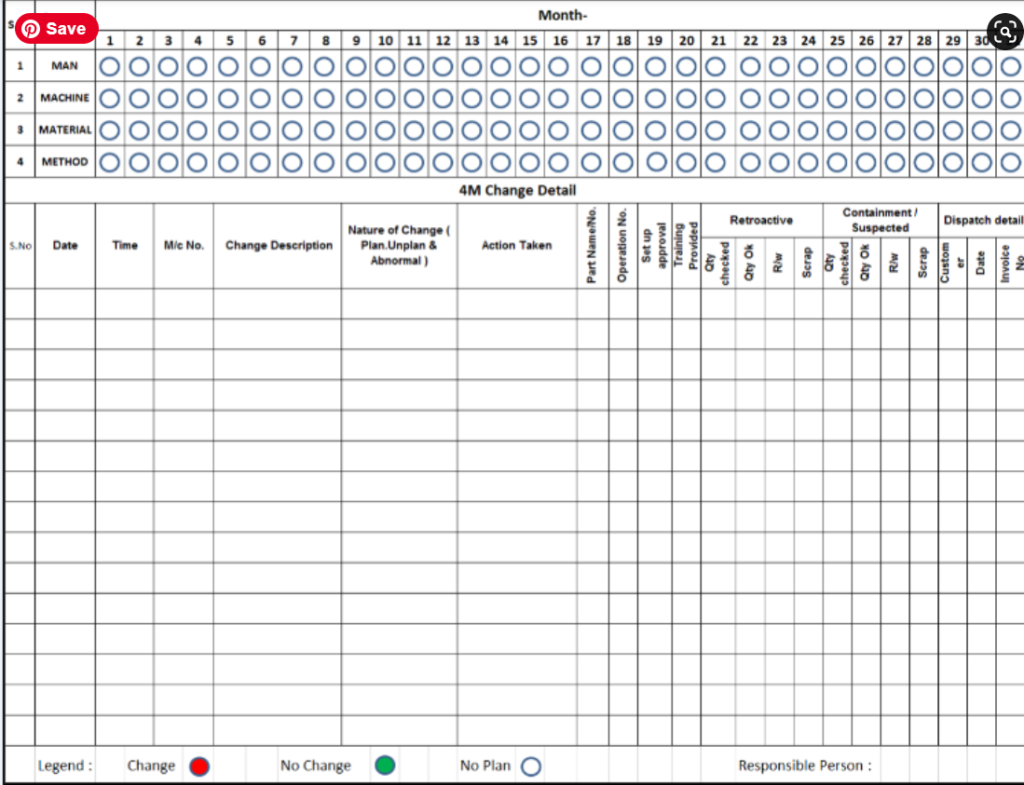

If there has been no change, the 4’M change accountable person should fill out the tracking sheet in green; if there has been a change, he should fill it out in red.

If there is a change, the relevant departments must be informed, and control measures must be performed in accordance with the WI.

Benefits of 4M Change Management

The defect is simple to track at the supplier end.

It assists in finding problematic products in the case of an OEM recall.

When OEM and Tear1 firms receive 4M change data from their supplier in a timely manner, it gives them trust.

Reduction in rework and rejection.

WI For 4M Change Management:

Examples of Man Changes in 4M Change

The operator with the information is on leave.

Operator absent and uninformed (start of shift)

a new user operating the equipment

operative on extended leave ( More than 45 days)

Operator leaves work unexpectedly after an accident

Operator leaves work unexpectedly due to sickness

Points 1 through 4 in the instances above are planned changes, while points 5 through 6 are unplanned changes. It is acceptable to only approve setups if we employ operators with the same competence level in all circumstances. However, it becomes an abnormal circumstance if we have to engage an under-skilled operator. Take confinement action from that day as well (100% visual inspection & 5 parts recording).

Provide new operators with training in accordance with operating standards and take efforts to contain all products for that day. Take retroactive inspection of all parts from previous inspections to check for unanticipated changes.

Machine(Tool)Change Examples in 4M change:

Machine being maintained proactively.

A machine that’s broken

Newly installed machinery

Preventive maintenance tool

Currently broken down

Utilized a new tool

Example of a 4M modification for Material & Method:

Material received from another authorized supplier

Information obtained from an unreliable source

various grades of material

Changes in process parameters

Changes in layout

Process technique modification

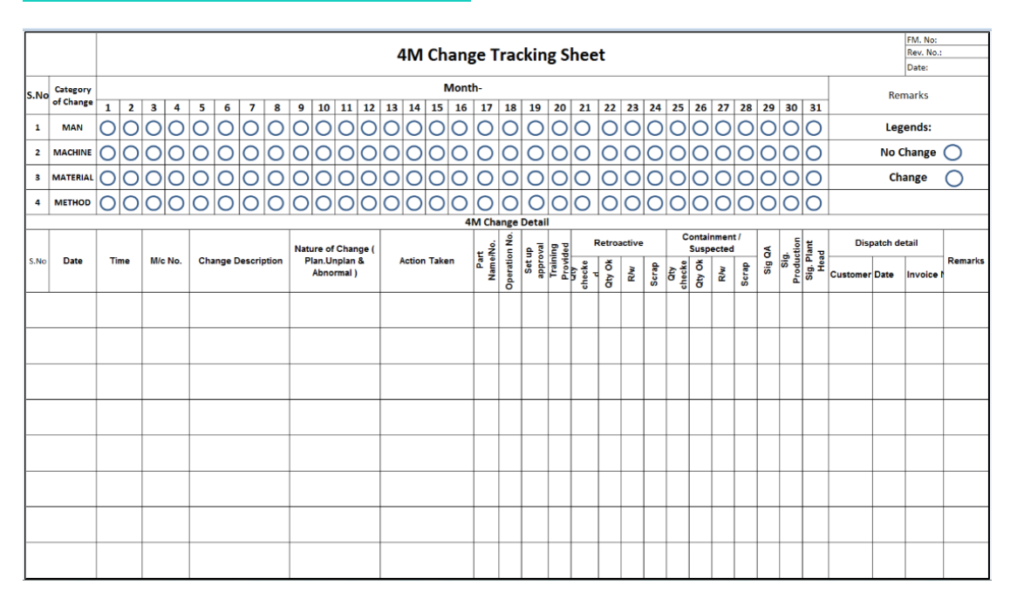

A description of all the process modifications and their specifics are prepared for the 4M CHANGE TRACKING SHEET. It includes the commencement date of the change, Changes to the description, the change’s type, the actions that were taken, Machine or tool information, part names, retroactive records, containment records, and dispatch information, among other things.

4M Change Tracking Sheet:

We create a summary of all process changes together with their specifics for the tracking sheet. It includes the commencement date of the change, Type of change, description of changes, What was done during the change, detail of a machine or tool, Name of the part, any retroactive records, containment records, dispatch information, etc.

4M Change Control Board:

Within 30 minutes of a modification, we update the 4M change control board with all of the process changes and their specifics. It includes the date and time the change began, Changes to the description, the change’s type, the actions that were taken, Detail of the machine or tool, Part name, Record of Retroactive Check, Record of Containment, and Dispatching Information, etc.

Man- Machine Matrix :

It is the operator and process matrix (machine). The supervisor can quickly determine which operator is qualified to operate the machine for each step using this matrix. It also goes by the name skill matrix.

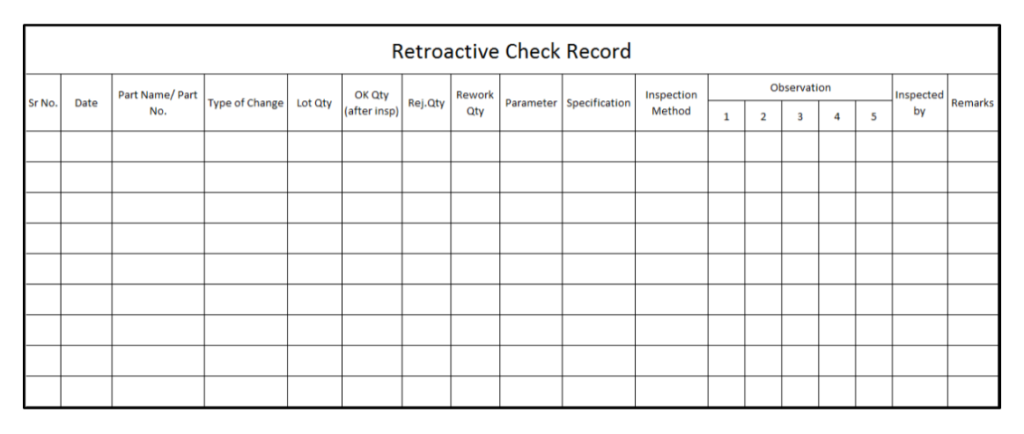

What does 4M change’s “Retroactive Inspection” entail?

Retroactive inspection involves examining suspected parts that were created before any unanticipated or abnormal changes occurred.

The following format is used to keep track of retroactive inspection records. This format is used to record the total inspection quantity as well as the quantities for OK, OK, Rejected, and Rework. Maintain sample quantity records as determined by the 4M modification.

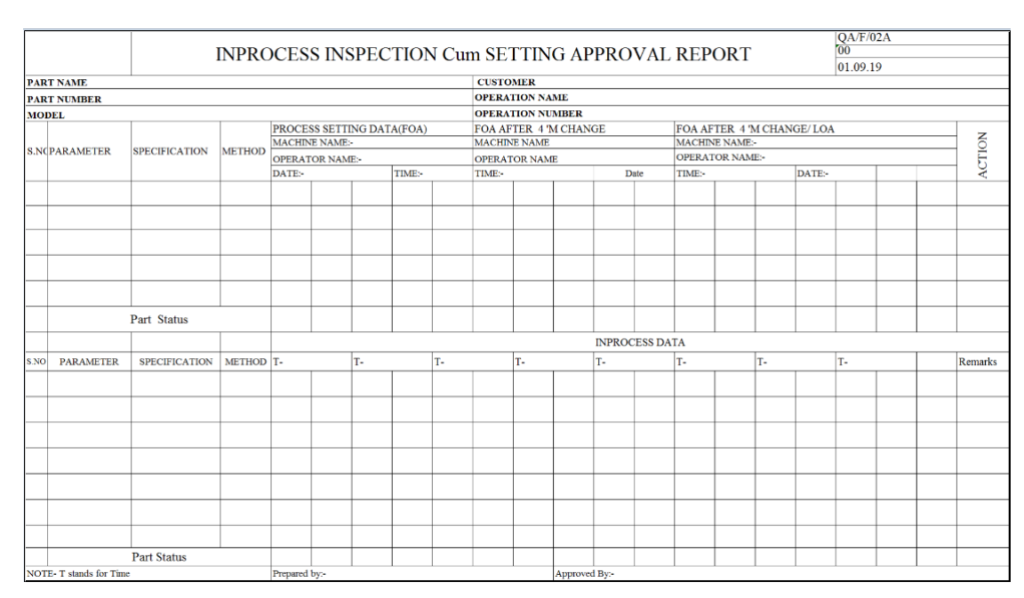

4M Approval Report :

When a process is restarted following a change and sample pieces are examined for approval, the procedure has been approved. It should be approved by the plant manager, the quality head, or the customer.

Join Courses:

- Certified Quality Manager

- Certified Operational Excellence Manager

- Certified Quality Inspector

- Certified lean Expert Gold-Level 3

- Certified Minitab Expert

- Certified 5S Expert

- Certified KAIZEN Expert

Other Articles:

#4m change management #4m change management in hindi #4m change management pdf

#4m change management matrix #what is the purpose of 4m change management,

#4m change management in automotive industry #what is a 4m change #benefits of 4m change

#4m change management process